The Applied Mechanics & Vibrations Laboratory (AML/UPAT) is in operation since 1980.

It is part of the Department of Mechanical Engineering and Aeronautics, University of Patras (UPAT).

AML/UPAT deals mainly with the general field of materials and structures giving emphasis in the science, the technology and the applications of composite materials (organic and ceramic matrix), monolithic ceramics and plastics.

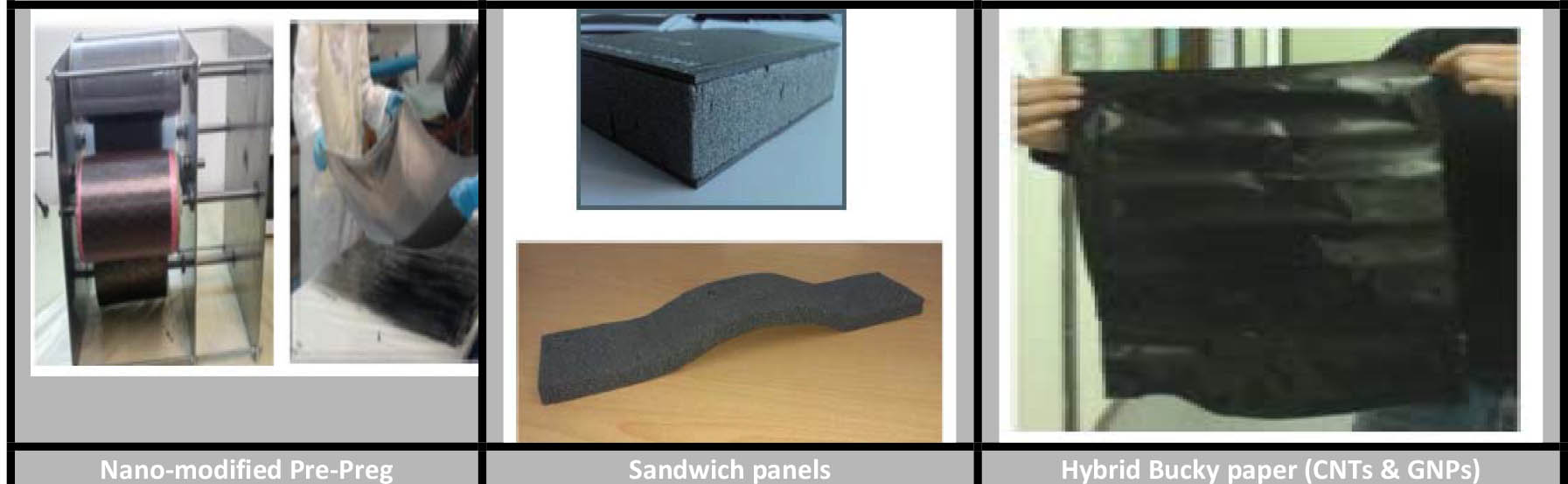

AML/UPAT has among others extensive experience in the field of Nano modification of thermoset resins, elastomers and thermoplastics, as well as the incorporation of namo-particles into Fiber Reinforced Composites for the manufacturing of multi scale reinforced Composite Materials. The nano-particles are introduced to the composites following different routes and has been successfully incorporated both in autoclave and out of autoclave manufacturing processes. The introduction of various types of nano-particles (both carbon based (CNTs and Graphene nanoplatelets) and/or inorganic ones), at relatively low % weight content, concludes to multifunctional composites with improved fracture and fatigue behavior, and tailored electrical, thermal and fire-resistant properties. Three different approaches have been followed for the introduction of nano-particles in to the host composite environment, namely: nano-augmentation, nano-engineering and nano-design. The nano-modified composites have been applied in various fields of structural composites such as aeronautics and surface transport, security and defense, as well as for the design of sensors, actuators and energy storage systems.

Furthermore, AML/UPAT has extensive experience in the LOW ENERGY, Out of Autoclave manufacturing processes of composites by using for the curing process microwave sources and IR technology (led based).

Especially in the direction of microwave curing AML/UPAT has proven the positive effect of the presence of low wt% content of CNTs for the microwave curing of epoxy systems (Journal of Applied Polymer Science (2013), Vol. 129 (5), pp. 2754-2764) and based on the our internal work we have concluded to a more generic result that says that in the case of using microwaves for the curing of different polymeric systems, in order to increase the energy absorption electrical conductivity of the level of 1 S/m or higher is needed. To that direction the use of either CNTs or electrically conductive routes of graphene for the modification of polymers plays a beneficial role.

Educational activities include twenty-one formal courses offered at undergraduate and graduate level dealing with the mechanics, stress analysis, design and optimization of composite materials and advanced structures, damage tolerance design, non-destructive testing, wave propagation and scattering theory, anisotropic elasticity, nanomaterials science and technology, nanocomposites manufacturing methods, recycling of composites and reuse of thermoplastics for the manufacturing of GRPs, low energy curing (IR and microwaves), life cycle analysis of composites, etc.

Qualified graduates may enroll in the PhD four-year program also offered by the Laboratory. AML/UPAT is highly internationally recognized for its contribution in the respective fields through books, lectures, research papers, conferences, professional society activities and research co-operation within the frame of financially supported projects, both by national and international Institutions, mainly by the EU.

AML/UPAT has in its permanent staff 5 university professors and 12 PhD holders (working in the field of Composite Material, Structural Dynamics, Non-Destructive Testing and Numerical Methods) and 6 technicians and support staff. Currently, 25 Engineers and PhD students are working in the Lab. (8 out of them are females). During the last 10 years 23 PhD theses have been completed in the general field of Mechanics of Composite Materials, Structural Dynamics and SHM & Non-Destructive Inspection of Materials and Structures, nanocomposites and nanomaterials science and technology. The highly trained and internationally experienced group of AML/UPAT offers a wide range of services on developing and prototyping innovative ideas and technologies, maintaining a high readiness level to deliver novel solutions and tools to the global market.

AML/UPAT is accredited by the National Accreditation System S.A (ESYD) in the fields of EN17025 (mechanical tests for metals, plastics and composites at ambient and elevated temperatures), EN17020 (transport of dangerous goods (2005), EN 17020: certified for the application of ΕΝ 62446 (Minimum requirements for the documentation, operation mode testing and inspection of Photovoltaic systems connected to the grid and its normative references HD 60364) and EN 17020: responsible entity for the application of the EU regulation in Greece, for the testing of seat belts, bumpers and seats for school buses.

AML/UPAT is among a limited number of Research Laboratories word wide that has the capacity of working with nano-particles following strictly the Health and Safety Regulations, and the major EU nanoparticles producers, (NANOSIL, BASF, ARCEMA) after audit provide the Lab with large quantities of various nano-particles. AML/UPAT participates in EU H2020 NMP program PLATFORM, where among others standardization activities for nano-modified composites are developed. AML/UPAT has participated in more than 40 European collaborative projects during the last 15 years.

AML/UPAT has participated in more than 40 European collaborative projects the last 15 years.

- FP 6, EU-STREP: “Aerospace Nanotube Hybrid Composite Structures with Sensing and Actuating Capabilities”, NOESIS, 2004-2008.

- FP 7, EU-L1: ‘Multifunctional Layers For Safer Aircraft Composite Structures’, LAYSA, 2008-2010.

- EU AAT L1: Novel Aeronautical Multifunctional Composite Structures with Bulk Electrical Conductivity and Self-Sensing Capabilities, ELECTRICAL, 2010-2013.

- FP7-L2: Smart Intelligent Aircraft Structures, SARISTU, 2011-2015

- EU AAT L1: Advanced technologies for bomb-proof cargo containers and blast containment units for the retrofitting of passenger airplanes, FLY BAG2, 2012-2016.

- ESA, GSTP program, Nanotube Reinforced Structural Materials for S/C Applications, NAREMA, 2010-2012.

- EU Clean Sky JU, Eco-Design ITD, Study on the processing and the performance of cyanate ester composites towards the optimization for harsh service environments, SPECIMEN, 2011-2013.

- ESA, GSTP program, Non-Conventional CNT- Skeleton Reinforced Composites for Application in Space (Follow-On activity), NACO2, 2011-2013.

- EU AAT L1: Self-Healing Polymer for Concepts on self-Repaired Aeronautical composites, HIPOCRATES, 2013-2015.

- EU-JTI- Clean Sky: “Industrialization of Out-of-Autoclave Manufacturing for Integrated Aerostructures”. IRIDA, 2011-2014.

- EU-JTI-Clean Sky: “Manufacturing optimization of a plenum with GFRP cyanate ester-based prepreg”. PLENOPTIMUM , 2014-2016.

- ESA, NPI projects: Methodology for Innovative Health Monitoring of Aerospace structures using Dynamic Response Measurements and advanced signal process. (MINERVA), 2009-2013.

- EU FP 7-REG “Reinforcement of recycled PE by using natural fibers coming from wood wastes”, REFIPLASR, 2013-2015.

- Greece-Germany research collaboration, GRACE project: Novel graphene modified CFRPs for improved damage tolerance behaviour and multifunctional characteristics,

- 2014-2016. ESA TRP: “Graphene-based systems for enhanced energy storage”, GADGET, 2015-2017.

- ESA TRP: “Graphene-based advanced polymers with high thermal and electrical conductivity”, GOETHE, 2015-2017.

- EU H2020 NMP: “Open Access pilot plants for sustainable industrial scale nanocomposites manufacturing based on buckypapers, doped veils and prepregs”, PLATFORM, 2015-2018.

Description of the capabilities of the entity, significant infrastructures, technical equipment, design and test tools, facilities:

- Mechanical and NDI Testing:

3 Hydraulic Universal Testing Machines (Maximum capacity, 25kN 100kN and 250kN, Maximum frequency for fatigue testing 100 Hz), Equipped with furnace, working from sub-ambient temperature up to 1000oC. ASTM standards jigs.

1 Electromechanical Universal Testing Machine (Maximum capacity 25 kN).

Low velocity Impact test set up

Special frame for testing of safety helmets according to EC regulation 22.

Equipment for creep and relaxation tests for temperature up to 500oC.

Custom made equipment for wear, friction and Fretting Fatigue measurements

National Instruments PXI-1033 with PXI-4071 DMM & PXI-2530 SWITCH for parallel monitoring of electrical resistance during mechanical testing

Ultrasonic Systems, A, C and D-Scan (Bath Size 1200x1000 mm)

Acoustic Emission Systems

- 6-channel SPARTAN 2000 system by PAC for NDT Acoustic Emission Analysis.

- 4-channel MYSTRAS system by PAC for transient Acoustic Emission Analysis.

Thermo-camera system by Nikon.

High speed Digital Image Correlation System (DIC) and Non-contact displacement measuring systems: Laser Doppler Vibrometer.

Fully equipped machine shop capable of precision processing for the commissioning of prototype equipment (jigs, fixtures and similar test devices) and structural components (e.g. joints)

- Physical Characterization:

DuPont2000 Thermal Analysis system with TMA-943, DMA-983, DSC-910 and LNCA II.

Mathis-Instruments TCI-Thermal conductivity Analyser with low K module (K-range 0,04-10 W/mK)

DC bulk conductivity setup using KEITHLEY DMM 2002 Digital Multimeter

Dielectric Spectroscopy Alpha-N Frequency Response Analyzer by Novocontrol

Full access to a number of SEM, Atomic Force Microscope, Microprob, XPS and optical microscopes for material and fractographic analysis.

- C. Nano-composites fabrication:

DISSOLVER and TORUS-MILL shear mixing devices and ULTRASONIC TIP/BATH

MAGNETIC HOT PLATE STIRRERs

Calander shear mixing device (3 roll mixture)

Glove Box and Fume Hood for safe material handling

- Composite Manufacturing Equipment

Autoclave, RTM, VARTM, Infusion, Vacuum Bugging

Prepreger machine

3 x conventional curing Ovens and 1x microwave Oven

Thermal Press equipment 500x500 mm2 (max temp 400oC, 350kN)

2 Micro extruder devices for engineering plastics (PEEK, PEI)

Electrospinning and MELT electrospinning Equipment

Various polishing and cutting devices (LaboPol-1, Minitom etc)

- Vibration and modal Analysis:

Experimental Modal Analysis: Modal frequency, Modal damping, Mode shapes

Various types of excitations

High-voltage dynamic excitation of piezoceramic actuators (±700Volts)

2 base excitation shakers, excitation hammers, data logger and data acquisition systems.

Sensory voltage, dynamic acceleration, force, strain and temperature measurement

Various 8-and 4-channel high-speed dynamic data acquisition & spectral analyzer systems

Fibre Bragg Grating system with dynamic optical sensing interrogator for vibration analysis, wiith capacities to attach/bond FBGs.

Damping measurement capabilities (both for material and structural damping).

- Environmental & Conditioning:

Outgassing: Low Vacuum Chamber for preliminary tests

Conditioning chamber for humidity, temperature control and UV radiation.

Hydrothermal Baths

Conditioning - chamber for below zero temperatures.

- Micro-Characterization:

Full access in Environmental SEM (SUPRA) and optical Microscopy and Fractography, TEM, AFM and HARMONICS system, Nano – Indenter.

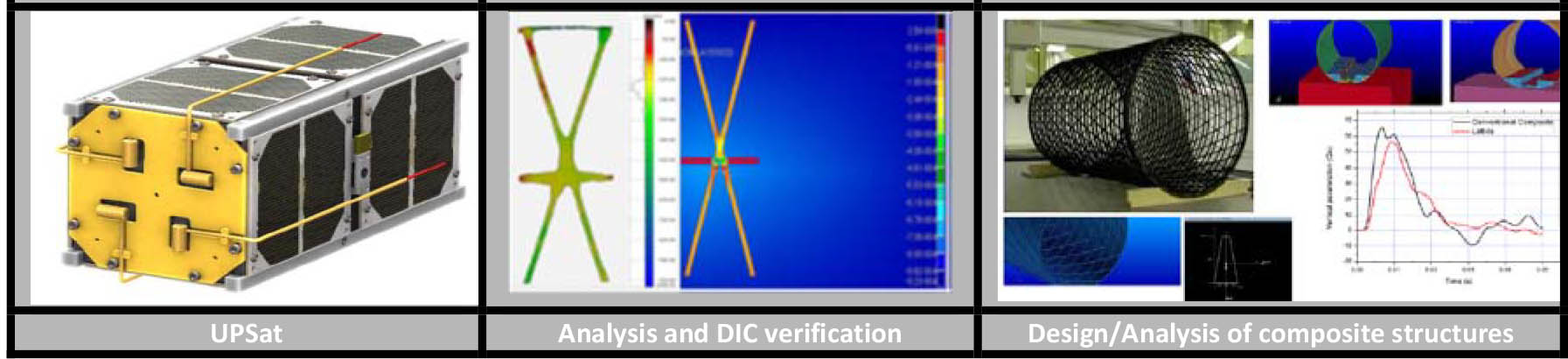

- Design and Analysis:

4 SUN Ultra 60 and 4 SUN Ultra 40 dual processor workstations operating independently or in a cluster

More than 10 PC Workstations of various configurations also available as a cluster

The following CAD Software are available: CATIA v5, SolidWorks, Unigraphics, Rhinoceros.

For Structural Analysis the following FEA Packages are used: MSC Patran/Nastran/Sinda, MSC Thermica, LS-DYNA, ESA-Comp, FEMB, ModeFRONTIER, NX Nastran.

For Multi-physics Analysis, the following FEA packages are used: ANSYS, ABAQUS, ThermXL, ESATAN/ESARAD.

For nano-scale modelling DIGIMAT software is also available.

UPat/AML maintains an extensive Technical Library with up-to-date information and reports on topics of composite materials and structures. In addition, it has academic access to all major scientific journals and reporting houses in fields relevant to spacecraft materials and structures.